← Back to Topics

ESP Design – Hand Calculations guide

Production-Surveillance-Intervention — Artificial Lift

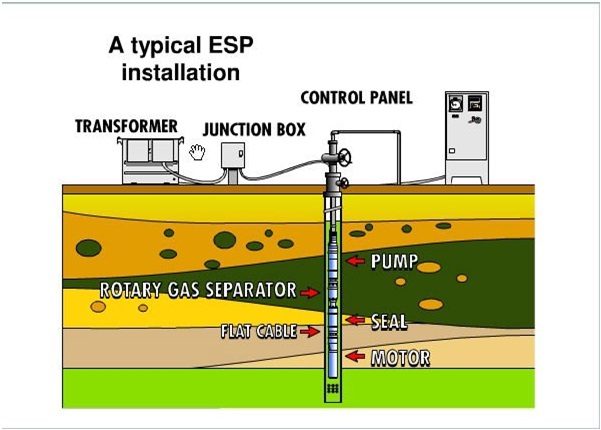

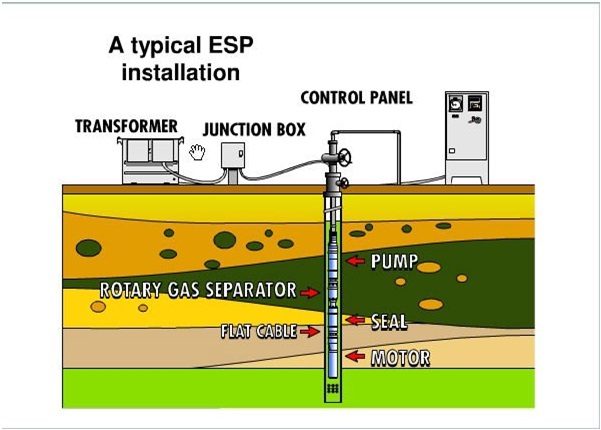

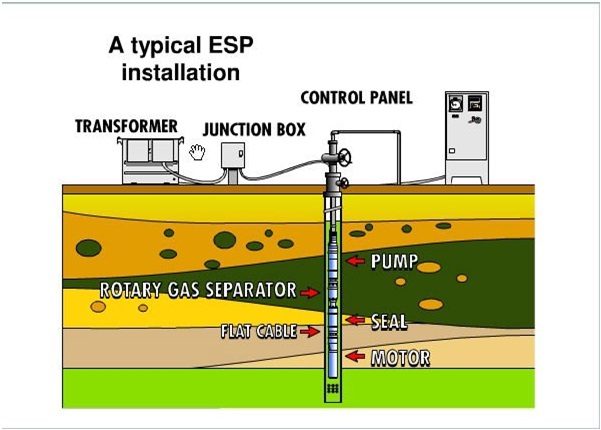

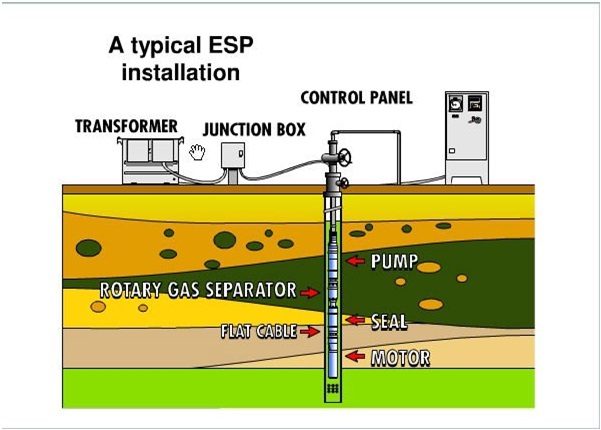

The ESP Design – Hand Calculations guide provides a step-by-step walkthrough for designing an Electrical Submersible Pump (ESP) system, especially useful for wells producing water and light crude oil. Here's a summary of the 9-step design procedure:

🧩 1. Basic Data Collection

Well profile, casing, tubing, perforation depth

Fluid properties: API gravity, water cut, GOR, pressures, temperatures

Production targets and power availability

📈 2. Production Capacity

Uses Productivity Index (PI) to estimate inflow performance

Calculates flowing bottomhole pressure (Pwf) and pump intake pressure (PIP)

💨 3. Gas Calculations

Determines free gas volume at pump intake

Uses Standing’s correlation for solution GOR

Calculates oil and gas formation volume factors (Bo and Bg)

📏 4. Total Dynamic Head (TDH)

Combines net well lift, tubing friction loss, and wellhead pressure head

Uses Hazen-Williams formula for friction loss

🔄 5. Pump Type Selection

Chooses pump series based on casing size and flow rate

Calculates number of stages and required brake horsepower (BHP)

⚙️ 6. Compound Sizing

Selects seal, motor, and evaluates gas separator need

Motor selection considers frequent starts/stops and voltage requirements

🔌 7. Cable Selection

Determines cable size, type, and length

Calculates voltage drop and power loss for cost analysis

🛠️ 8. Accessory Equipment

Includes motor lead extension, cable bands, protectors, check valves

Surface equipment like Variable Frequency Drive (VFD) and transformer taps

📊 9. Final System Integration

Ensures all components are compatible and optimized for performance and cost.

ESP Design Form is here

🧩 1. Basic Data Collection

Well profile, casing, tubing, perforation depth

Fluid properties: API gravity, water cut, GOR, pressures, temperatures

Production targets and power availability

📈 2. Production Capacity

Uses Productivity Index (PI) to estimate inflow performance

Calculates flowing bottomhole pressure (Pwf) and pump intake pressure (PIP)

💨 3. Gas Calculations

Determines free gas volume at pump intake

Uses Standing’s correlation for solution GOR

Calculates oil and gas formation volume factors (Bo and Bg)

📏 4. Total Dynamic Head (TDH)

Combines net well lift, tubing friction loss, and wellhead pressure head

Uses Hazen-Williams formula for friction loss

🔄 5. Pump Type Selection

Chooses pump series based on casing size and flow rate

Calculates number of stages and required brake horsepower (BHP)

⚙️ 6. Compound Sizing

Selects seal, motor, and evaluates gas separator need

Motor selection considers frequent starts/stops and voltage requirements

🔌 7. Cable Selection

Determines cable size, type, and length

Calculates voltage drop and power loss for cost analysis

🛠️ 8. Accessory Equipment

Includes motor lead extension, cable bands, protectors, check valves

Surface equipment like Variable Frequency Drive (VFD) and transformer taps

📊 9. Final System Integration

Ensures all components are compatible and optimized for performance and cost.

ESP Design Form is here

💬 Comments

✍️ Leave a Comment